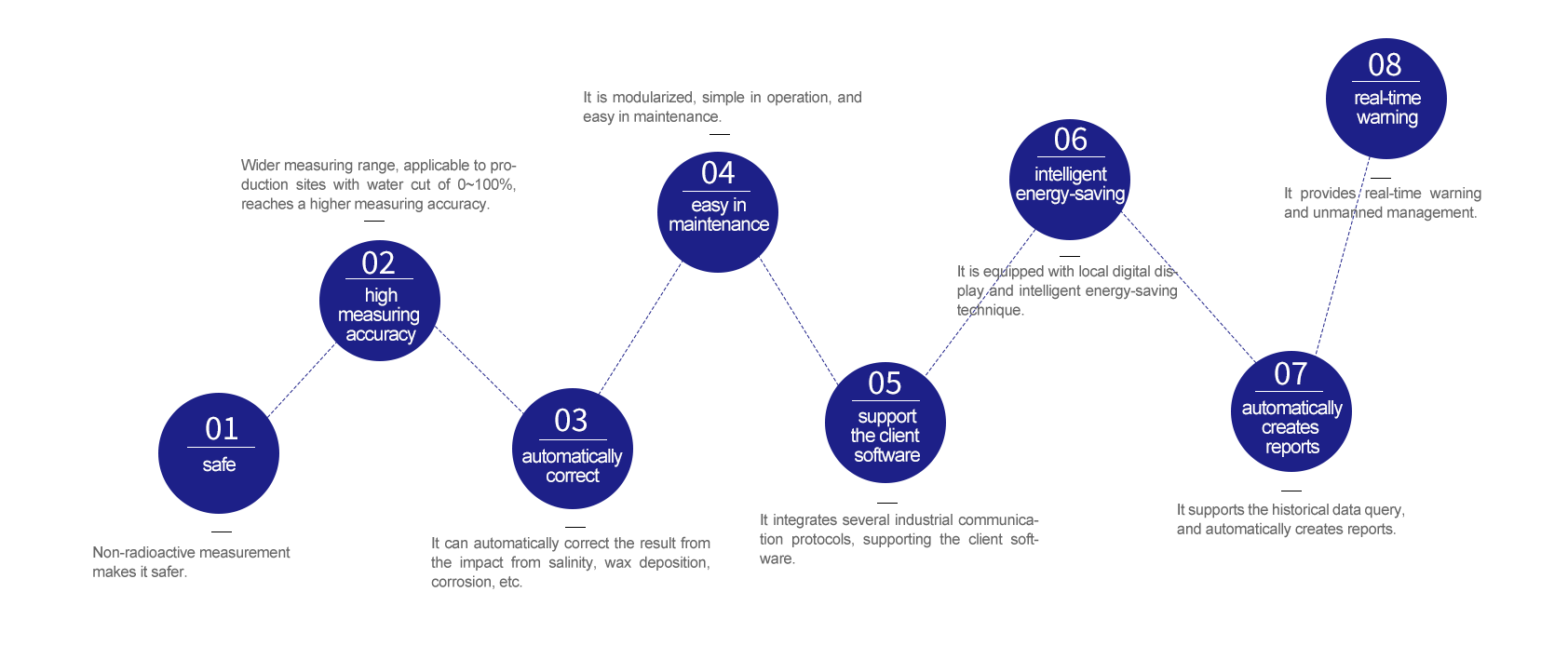

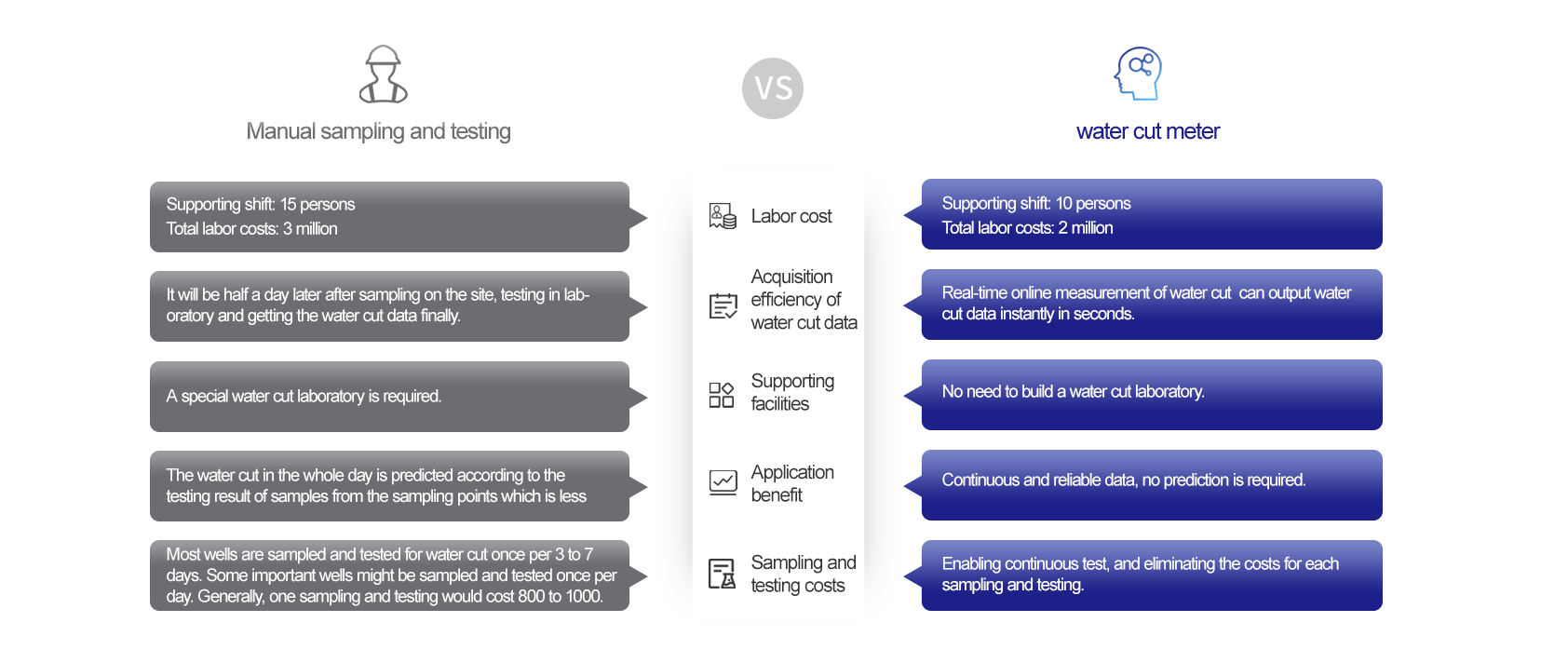

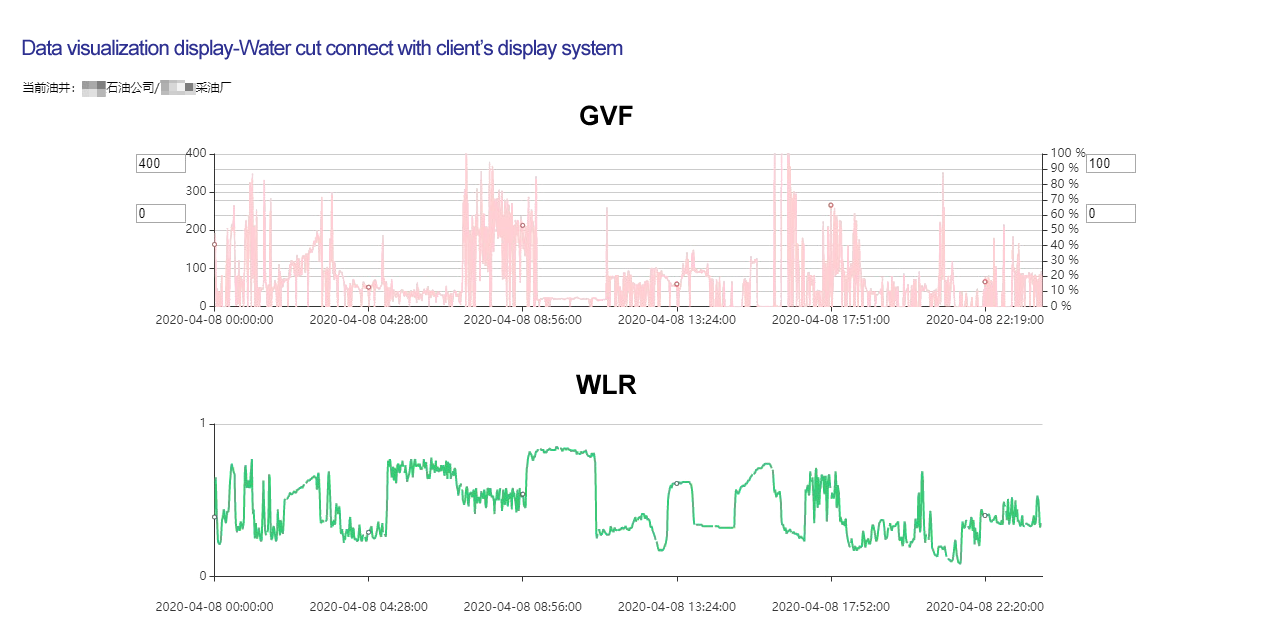

By utilizing its technique of microwave measurement, LeEngStar creates the water cut meter which are suitable for varied production sites.

This kind of products model the difference of transmission characteristics in different fluid medium (i.e., oil, water and emulsion) by the microwave sensing technique, analyze and compare the signal amplitude and phase phase shift and then get the water cut of the measured medium. LeEngStar’s intelligent water cut monitor is designed at the industrial grade, which can be applied in a wide range of demanding industrial environments, including full range water cut conditions, acidic conditions, heavy oil conditions, etc. This product is applicable to monitor the crude oil ranging from 0 to 100% in water cut, with high measure accuracy and stability. This product is specially designed a unique algorithm for the high water-cut wells (water cut > 80%) that enter the late stage of production in China, so as to fulfill the higher requirement of accurate data in single well water cut measurement.